by Fuji Shoko, Japan

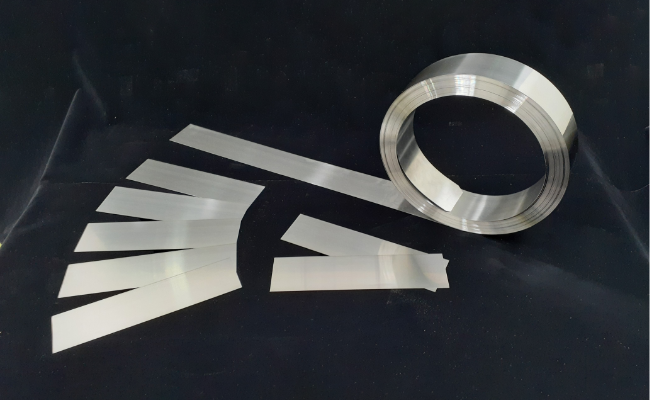

Fuji Shoko has developed our "Katana" doctor blade series full of trust and tradition, by all the processing performed in Japan.

doctor blade manufacturing : Material, Blade and Coating.

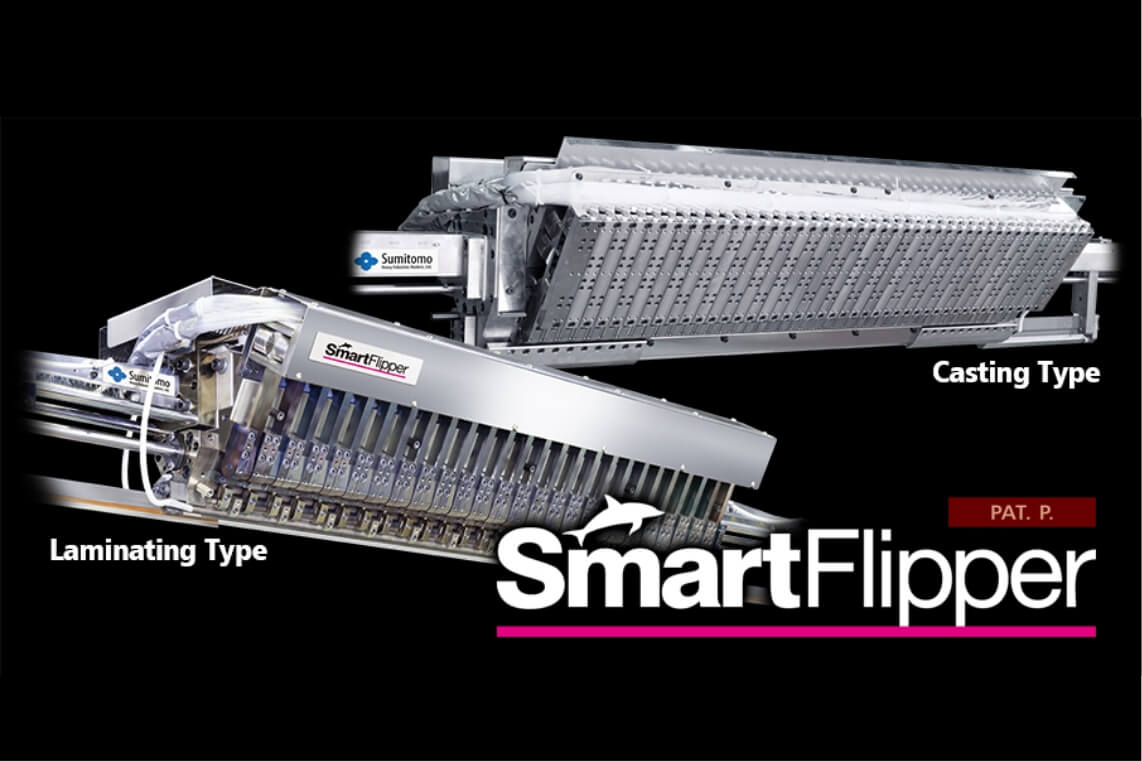

high performance converting/web-handling machineries.

Ask for more product information!

It can be installed any type of web converting machinery, including print press, rewinder, laminator and etc.

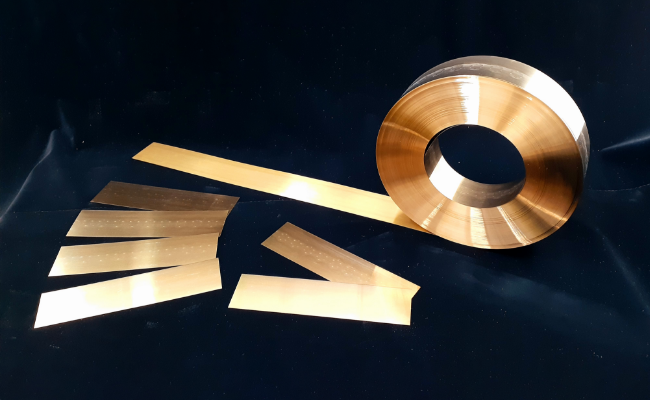

“Tama-Hagane”, meaning a special kind of precious steel in Japanese, also known as the material for Katana swords, is only produced in very limited quantities through Western Japan’s traditional "Tatara Steelmaking" process. With its high purity and superb uniformity, Tama-hagane has consistently been used to enable the capabilities of Katana swords. Today, the original steel making techniques have evolved into present Japanese specialty steel production. These materials based on ancient technologies are not only used to make knives and blades, but are also used to meet the world’s modern demands from the electronics, automobile, energy, and other advanced fields.

As part of Katana crafting, advanced polishing technologies were developed to achieve a perfect balance between function as a sword and beauty as an artwork. The quality of polishing is said to determine the value of Japanese swords, and apart from swordsmiths, there also existed specialized "sharpeners" who were entirely dedicated to the polishing process throughout their lives. Similarly, our experienced blade specialists engage in realizing exquisite sharpening finishes day after day, developing original techniques passed down from our predecessor craftsmen of the past.

Since their introduction to Japan in the form of pottery more than 2,000 years ago, ceramics have undergone numerous transformations, ultimately evolving into today's advanced-ceramics for industrial needs. In addition to their natural heat-resistance and insulation properties, modern science and technology have developed the functionality of ceramics to an advanced levels. Likewise, we were able to design a ceramic coating with fine-grain, uniform particles to enable a high level of durability that can endure the harsh conditions experienced during printing and coating processes.

KATANA® Movie

Products

Find out more

Ceramic Doctor Hi-Blade® is a highest quality ceramic-coated model with great resistance against wear and abrasion.

MORE

Steel Doctor Hi-Blade® is manufactured under strict quality control, from materials to sharpening and final inspection.

MORE

Plastic doctor blade series are stable with organic solvent,

oils, greases and acid/weak alkaline solutions.

MORE

We have a variety of items that meets flexible packaging production needs, such as print press peripheral items, converting knives and etc.

MORE

About us

Locations

(Headquarters)